According to Michael Wenz GmbH, or MIWE, bakeries using a heat recovery system can recover about 25 percent of the total energy spent by baking ovens which is an average of about 600kwh a day. Bakeries use a lot of energy which is why heat recovery systems can bring a lot of benefits and savings. If you are interested in adding a heat recovery system for your bakery, what benefits you will get and how does it work then make sure you read our article until the end.

How do Heat Recovery Systems Work?

Creating new and efficient renewable energy technologies is not just about using the power of the sun, wind or water and feeding it into our homes, office buildings or in this case a bakery. Making the most out of what is already there will help reduce our impact as humans on the environment, and that includes the huge amounts of heat we lose every day to the environment.

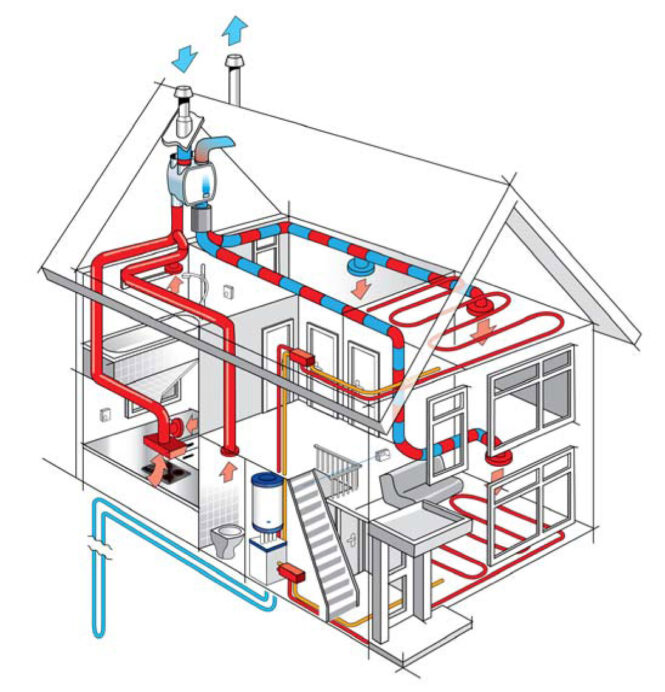

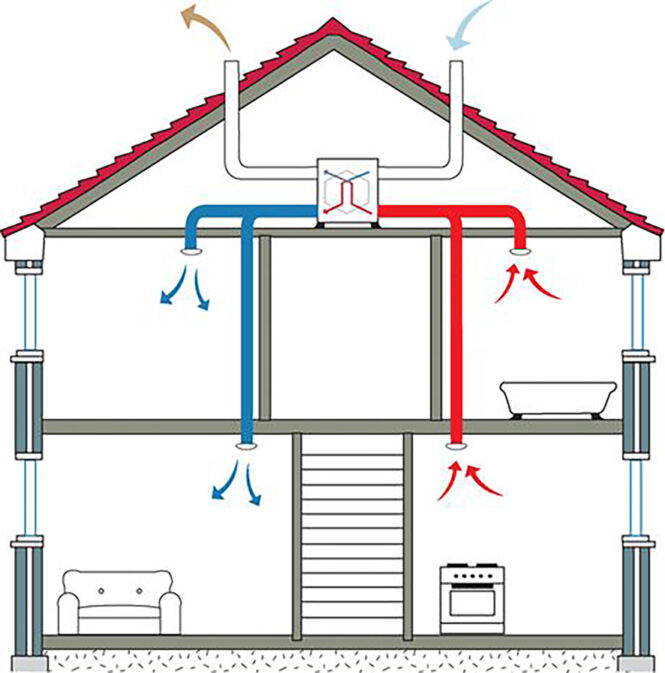

Heat recovery systems work by drawing that valuable warm air or water and then re-use that same heat.

In a world where technology like heat recovery does not exist, air circulated a bakery, becomes stale/old and is replaced by the colder air coming from the outside or warmed up by the ventilation system. But what happens to that already warm air? It simply gets back into the atmosphere. Heat recovery systems do not replace the need for a system to heat your radiators or a boiler but it does help them worm much more efficiently by recycling all that used warm air ensuring that you get the most out of it.

If you are looking for a heat recovery system, check out www.exodraft-varmegenvinding.dk

Why you should Get a Heat Recovery System?

A recovery system could help you save on energy bills by re-using the saved energy for heating. It is very easy to lose all that valuable heat in our homes, workspaces, or even bakeries. You just open a window or a chimney and all that warm air just flies up in the atmosphere. With a heat recovery system, you will constantly get fresh air while using the energy from the excess heat.

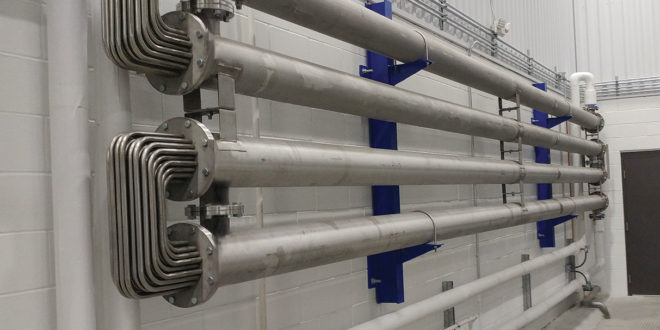

Some factories typically produce heat between 400 and 500 °C and some bigger bakeries can discharge air over 550 °C. The potential for large scale heat recovery is huge in these situations and can be a significant return on investment for a lot of businesses.

While heat recovery systems can be used to save energy when heating the furnaces, it can also be installed on boilers which can lead to huge savings and reduce the carbon footprint. Boilers work by converting the energy from gas, oil or biomass, for the purpose of heating water. This fuel is burned which results in the heat being transferred to the water.

During this process, the excess gas that is produced by burning the fuel leaves through a chimney. Because of this a lot of boilers that are used by bakeries are very inefficient because additional heat that is produced by the fuel is lost through the chimney, sometimes as much as 20%. Heat recovery systems can collect that excess heat and reuse it to heat up the boilers.

Imagup General Magazine 2024

Imagup General Magazine 2024