The art of metal stamping has its roots in ancient civilizations such as the Egyptians, Greeks, and Romans. These early metalworkers used a variety of techniques to create designs on metal objects, including hand-engraving and stamping. Hand-engraving involved using sharp tools to carve designs directly into the metal surface, while stamping involved impressing pre-made designs onto the metal using punches and hammers.

For example, the ancient Egyptians used both hand-engraving and stamping to create intricate designs on their jewelry and amulets, depicting hieroglyphs, animals, and gods. The Greeks used hand-engraving to create detailed scenes on their metal cups and plates, while also using stamps to create coins with images of their gods, heroes, and emblems. Similarly, the Romans used hand-engraving to create detailed reliefs on their metal sculptures and armor and also used stamps to mint their coins with images of their emperors, buildings, and military conquests.

Medieval Metal Stamps

During the Middle Ages, metal stamping became more sophisticated as craftsmen began to use chisels and other tools to create more intricate designs on metal objects. The stamps used during this time were made from higher-quality materials such as steel and copper, and they were capable of creating more precise and durable designs. Metal stamping played a vital role in creating decorative objects such as armor, weapons, and jewelry, and it was also used for practical purposes such as creating coins and marking tools.

For instance, medieval metalworkers used metal stamps to create elaborate designs on their suits of armor and weapons, often depicting scenes from history or myth. The stamps used for this purpose were large and complex, and they required a great deal of skill to use effectively. Medieval jewelers used metal stamps to create intricate designs on their pieces, which were highly valued for their craftsmanship and beauty. In addition, metal stamps were used to create coins, which were essential for trade and commerce during this period.

As the use of metal stamps became more widespread, the demand for skilled metalworkers increased. This led to the formation of guilds and apprenticeships, which helped to preserve and pass down the techniques of metal stamping to future generations.

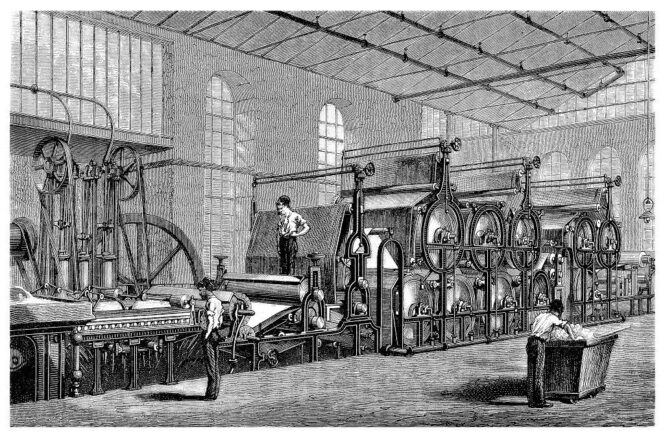

Industrial Revolution Metal Stamps

The Industrial Revolution brought significant changes to the metal stamping industry. With the invention of machines and the steam engine, it became possible to mass-produce metal goods. Metal stamping played an essential role in this process, as it allowed for the creation of precise and uniform markings on products such as firearms, machinery, and tools.

During the mid-1800s, the production of metal products increased dramatically. In 1850, the United States produced 111,000 tons of iron and steel products, while by 1890, that number had increased to 10 million tons. The use of metal stamps in the production of these goods was a significant factor in this growth. Metal stamps were used to mark products with identification numbers, trademarks, and other important information, helping to increase their value and authenticity.

Metal stamping also played a critical role in the production of coins during the Industrial Revolution. The use of machines allowed for the mass production of coins, which were used for currency and trade throughout the world. By the early 1900s, the production of coins in the United States had reached over one billion annually. Metal stamps were used to create the intricate designs and markings on these coins, ensuring their quality and authenticity.

Modern Metal Stamps

Today, metal stamps are made using a variety of modern techniques. One significant development in the metal stamping industry has been the use of computer-aided design (CAD) software to create highly precise designs. CAD software allows for the creation of intricate designs that can be transferred onto metal using advanced methods such as lasers, etching, or electroforming.

In addition to CAD technology, the United States government has played a significant role in modern metal stamping. The Department of Defense (DOD) has established rigorous standards for metal stamping and other manufacturing processes used in defense contracting. These standards ensure that the products created for the military meet the highest quality and safety requirements. The DOD has also implemented advanced technologies such as additive manufacturing and robotics to improve the efficiency and precision of metal stamping and other manufacturing processes.

The modern metal stamping industry has a wide range of applications, from creating intricate designs for jewelry and watches to producing high-precision components for the aerospace and defense industries. With the continued advancement of technology, it is likely that metal stamping will continue to play an essential role in the manufacturing of goods for years to come.

Artistic and Decorative Applications

Metal stamps have played a significant role in artistic and decorative applications throughout history. These specialized tools allow artisans and craftsmen to create intricate and precise designs on various metal surfaces. From jewelry making to ornamental metalwork, metal stamps have been utilized to add unique patterns, motifs, and personalized touches to numerous creations.

Artisans can use metal stamps to imprint their signature styles, initials, or symbols onto metals, adding a distinct identity to their work. The versatility of metal stamps enables artists to experiment with different textures, shapes, and sizes, transforming plain metal surfaces into visually captivating masterpieces.

Whether it’s embossing patterns on metal sculptures, engraving designs on silverware, or creating personalized imprints on jewelry, metal stamps continue to be a valuable tool in the realm of artistic expression. The fusion of traditional craftsmanship with modern design techniques has expanded the possibilities of metal stamps in art, enabling artists to push boundaries and create awe-inspiring works that captivate the eye and imagination.

Wrapping Up

The history and evolution of metal stamps are fascinating. From the ancient techniques of hand-engraving to modern technology, it’s clear that metal stamping has come a long way in recent years. With advances in technology, it’s no longer necessary for artisans to spend hours engraving intricate designs – instead, they can use computer software to create complex patterns with just a few clicks. Metal stamping remains an important part of many businesses today, as it provides an efficient and cost-effective way to customize products or create distinctive corporate logos.

Imagup General Magazine 2024

Imagup General Magazine 2024