Packaging is critical in safeguarding products during transportation to the customers and creating a pleasant customer experience. In many cases, it will be the first contact potential customers have with your business. This makes it essential to ensure that your packaging properly represents your brand.

Good packaging is created based on several factors, such as functionality, design, and brand image. However, with growing consumer demand for environmentally friendly products, businesses are beginning to consider the sustainability of their packaging. This includes using eco-friendly packaging, such as biodegradable custom mailer boxes, bags, and pouches. It also involves reviewing the impacts of your packaging on your environment to find out how you can improve them to become more sustainable, as well as eliminating the use of toxic materials in the production of packaging for your product.

This article explains the impacts of toxic materials on the environment and ways to minimize the use of toxic materials in packaging production.

The Impact of Toxic Materials on the Environment and Human Health

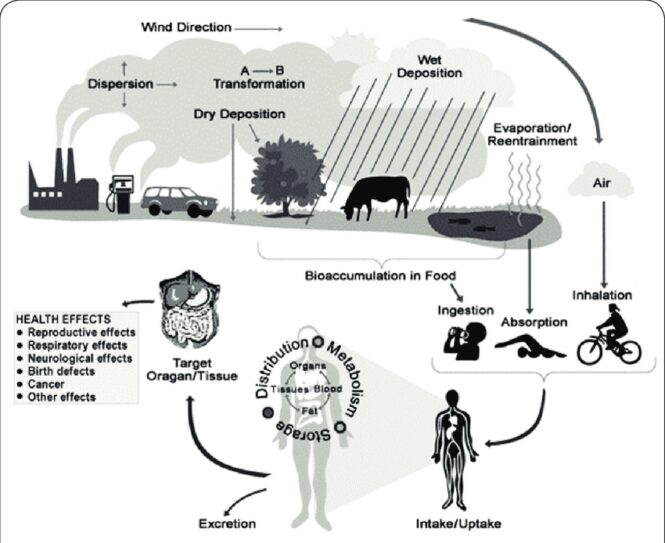

Toxic materials are substances that pose a risk to the environment and can cause harm upon exposure to the environment. The use of toxic materials in the production of packaging might also cause harm when people come across them through inhalation, skin contact, or consumption. Examples of toxic materials commonly used in packaging products include heavy metals, petroleum-based plastics, and harsh chemicals such as bisphenol A and phthalates.

When disposed of wrongly, toxic materials can contaminate soil and water, leading to ecological imbalance and long-term environmental damage.

Ways to Reduce the Use of Toxic Materials in the Production of Packaging

Here are some of the ways to eliminate the use of toxic materials in the production of your product packaging.

Assessment of the Current Use of Toxic Materials

The first step is to assess the current use of toxic materials in packaging production. This involves conducting a material and product analysis. Material analysis means examining the raw materials for the packaging to identify which ones have the potential to become a threat to the environment. On the other hand, process analysis involves analyzing the production processes to identify where toxic materials might be released during production.

The results from this analysis can help you to know which raw materials can be substituted for safer alternatives and to improve the production processes to minimize the release of toxic materials.

Substitution with Safer Alternatives

Switching to environmentally friendly materials is a crucial step to reducing the use of toxic materials in packaging production. For instance, you could adopt safer alternatives such as biodegradable materials, recycled materials, heavy metal-free materials, and natural materials. By substituting toxic materials with sustainable materials, businesses can improve the sustainability and safety of the packaging and minimize the environmental impacts of their business.

Redesign of Packaging

A great way to reduce the use of toxic materials is to redesign your packaging to reduce the number of raw materials for production. For instance, you could reduce the size and weight of the packaging to lower the number of raw materials required during the production stages. Or better yet, you could start a closed-loop system by designing packaging that can be easily recycled and reused to reduce the demand for virgin raw materials and the waste that comes from your business.

Redesigning your packaging to reduce the use of toxic materials can help improve sustainability, conserve resources, and minimize the environmental impacts of your business.

Awareness

Raising awareness about the impacts of toxic materials in packaging production can convince your stakeholders to reduce the use of these materials. You should also educate your customers about the dangers of toxic materials in packaging and the benefits of safer alternatives for the environment and human health. This will encourage them to make informed purchasing decisions and demand more sustainable packaging options.

It would help if you encouraged your suppliers to employ sustainable materials in their production processes. This will help to ensure that there are no toxic materials in your supply chain.

Use recycled materials

Using recycled materials in the production of packaging is a crucial step toward eliminating the use of toxic materials. Recycled materials can be sourced from a variety of sources, including post-consumer waste, industrial waste, and pre-consumer waste.

Post-consumer waste includes materials that have already been used by consumers, such as plastic bottles, cardboard boxes, and aluminum cans. These materials can be collected through recycling programs and repurposed into new packaging products. Industrial waste refers to waste generated during the manufacturing process. This can include materials such as scrap metal, wood shavings, and textile waste. Repurposing these materials into new packaging products can help reduce the amount of waste produced by the manufacturing process.

Pre-consumer waste refers to materials that are discarded before they reach the consumer, such as misprinted packaging or excess material from the manufacturing process. These materials can be collected and repurposed into new packaging products, reducing the amount of waste generated by the manufacturing process.

Continuous Improvement

There is always room for improvement. You should continuously monitor the sustainability practices to evaluate your progress and find out how to improve your production process. This will ensure that the use of toxic material for packaging production is minimized and that the production team prioritizes safer alternatives during production.

The Importance of Eliminating Toxic Packaging for a Sustainable Future

Eliminating toxic packaging is a critical step toward achieving a sustainable future. Toxic materials, such as plastic and heavy metals, are commonly used in packaging production and can have a devastating impact on the environment and human health. Here are some of the reasons why it is essential to eliminate toxic packaging:

- Environmental Impact- The production and disposal of toxic packaging materials contribute to environmental pollution and degradation. Plastic packaging, for example, takes hundreds of years to decompose, and the majority of it ends up in landfills or the ocean. These materials not only harm wildlife but also pollute the air and water, affecting human health and well-being.

- Resource Conservation- Eliminating toxic packaging can help conserve natural resources. Sustainable materials, such as bamboo, paper, and bioplastics, are renewable and biodegradable, reducing their impact on the environment. Additionally, using recycled materials in packaging production reduces the demand for new materials and the amount of waste produced.

- Public Health- Toxic materials in packaging can release harmful chemicals into the air and water, posing a threat to human health. Exposure to these chemicals can cause respiratory problems, allergic reactions, and even cancer. By eliminating toxic packaging, we can reduce the risk of exposure to harmful chemicals and improve public health.

- Economic Benefits- Eliminating toxic packaging can also have economic benefits. Sustainable materials and practices are often more cost-effective in the long term and can lead to reduced production costs and increased efficiency. Additionally, investing in sustainable packaging technology can create new jobs and spur economic growth.

In conclusion, eliminating toxic packaging is essential for creating a sustainable future. By reducing the environmental impact of packaging production, conserving natural resources, improving public health, and promoting economic growth, we can build a better future for ourselves and future generations. It is crucial for individuals, businesses, and governments to work together to promote sustainable packaging practices and create a more sustainable future.

Imagup General Magazine 2024

Imagup General Magazine 2024