IT hardware is sensitive to all sorts of climatic changes. Thus, any external impact can cause system malfunction, failure, and downtime. This is why it is crucial to monitor the climatic conditions in which server racks and hardware operate.

A server rack monitoring system is a set of sensors, controllers, and accessories aimed at controlling if climatic conditions in data centers are optimal for hardware operation. These are organized systems, where each device or unit is responsible for monitoring certain parameters.

Why is it Important to Monitor Rack Parameters?

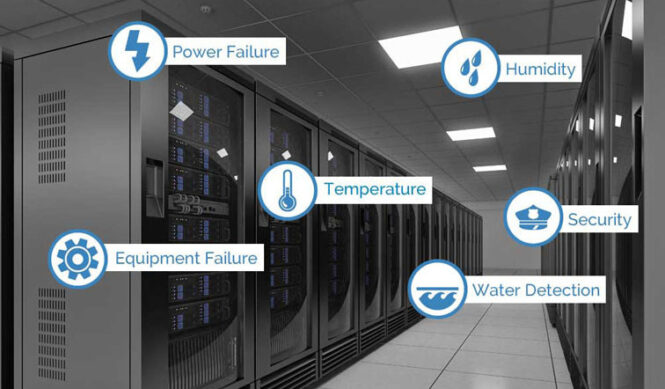

The importance of climatic conditions control is explained by network equipment sensitivity. A properly functioning control system allows controlling the following parameters:

- humidity to avoid corrosion or static voltage accumulation;

- temperature to avoid overheating;

- sufficient power supply to make sure that all devices get enough feeding to work properly;

- vibration to reduce the level of equipment depreciation;

- security to know who and when accesses hardware.

That is, server rack controlling allows controlling system functioning and maintaining the required conditions for its smooth running.

Types of server Rack Monitoring Devices

Diverse devices for server rack control are offered on the modern market. Specialists can pick suitable solutions for any type of server furniture and kind of system. The following tools are the most popular and effective.

1. Power monitoring (PDU)

The power supply monitoring system helps ensure the continuous collection, storage, and analysis of equipment parameters. Based on the datum obtained, it is possible to draw conclusions about the current state and performance of systems, as well as make forecasts regarding their work in the future.

A power management system is a set of requirements and measures that help enterprises improve their energy performance. They allow solving the next tasks:

- control of electricity consumption by individual units and installations;

- continuous receipt of information from sensors and controllers about the state of technology;

- automatic or manual launch of algorithms to prevent or eliminate emergencies, for example, a power outage;

- sending alarms to specialists to troubleshoot problems in the event of power failures;

- control of power, voltage, and non-priority load management.

The integration of power monitoring sensors allows consuming less energy and reducing financial expenses on utilities since power is allocated efficiently.

2. Temperature sensors

Network hardware emits much heat during functioning, which can result in overheating. Thus, it is vital for any system to implement server rack cooling strategies to organize a timely exchange of cold and hot air and maintain optimal temperature conditions.

Server rack temperature monitoring implies the installation of sensors that control the compliance of heat in cabinets and rooms with set parameters. In an event of a temperature rise, the system will send an immediate warning to the control board to inform the tech staff of the necessity to check cooling tools and reduce the temperature.

The recommended number of temperature sensors may vary, depending on the system size. However, ASHRAE advises installing at least 6 sensors per rack. This number will allow controlling the airflow remotely and reacting to temperature surges promptly.

3. Humidity devices

Humidity is another climatic factor that can significantly affect IT systems. The thing is that violation of humidity conditions leads to vaporing. Condensation will settle on hardware and circuit boards causing rusting. Vice versa, too dry air results in electrical charge accumulation, which increases the probability of fire.

The best humidity level for data centers is 40%-50%. Maintaining this range helps ensure smooth and durable system functioning without troubleshooting.

4. Rack door sensors

Rack enclosures are lockable. Latches and door locks are used to improve equipment protection and limit access to IT devices.

Sensors are responsible for monitoring who, when, and how many times opened rack doors. These tools allow securing devices from unauthorized access and fixing every door opening. Thus, it is easy to find out who is responsible for malfunction in the case of damage.

They are installed on top or bottom of the rack and have infrared control sensors that react to a door opening.

5. Air pressure devices

The pressure sensor is a liquid crystal display in an aluminum housing. It includes special tubes that evaluate the air pressure, and then convert it or display its numerical value using an analog or digital signal.

6. Contact control tools

This is a type of resistance sensor that converts the primary movement of an element into a change in the resistance of the electrical circuit. With the help of such devices, forces, displacements, and sizes of objects are measured and controlled.

7. Vibration detectors

It is an accurate electronic device for recording the amplitude and frequency of vibrations of various objects. They are used to test production conditions, as well as various equipment. The use of a vibration detector allows determining the condition of various equipment that has rotating elements. One can judge the emergency or alarming state of objects from the received vibration level data.

Constant vibration leads to loosening fasteners over time, which means that hardware is at risk of damage. Special detectors are used to identify vibration and inform the staff about it.

How to Choose the Server Monitoring Device?

The issue is not easy since the tech staff should consider too many points and foresee many cases. First of all, make sure to answer the following questions:

- what are the needs of your business and its server system?

- how many servers do you plan to install?

- how many components does the system comprise?

- how many parameters do you want to control?

- what is the served area?

Once you find out answers to these questions, you’ll have a clear vision of what you need. Make a list of the required devices. Study the market, compare the offered options, and pick suitable ones. Consult specialists if you don’t understand the difference between models.

Note that there are devices for monitoring the environment on premises (data centers, rooms, and offices) and inside cabinets or racks. These are two different categories of products.

There are numerous platforms that allow setting up control panels and adjusting parameters remotely. Thus, system administrators get convenient tools to optimize the workflow.

Server rack environmental monitoring is an indispensable step in data center arrangement. The integration of control tools will help eliminate the probability of hardware damage, simplify specialists’ duties, and ensure uninterruptible and smooth operation.

Imagup General Magazine 2025

Imagup General Magazine 2025