Printed circuit boards are items that are used in almost every industry, and in most electrical devices. They are said to be the main support of the components, and they use conductive sheets to connect the electrical components in one device. There are many different types of PCBs and they can be manufactured in specific ways.

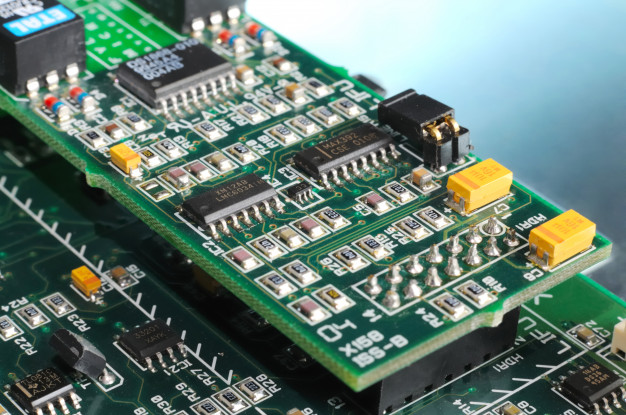

However, sometimes the manufacturing process is not perfect, and the green coating layer can do more damage than good. If the solder mask is not properly installed it could obstruct the functions of the device, and it can lead to damages or breaking of the item. In this article, we are going to talk about the removal process of the green coating from the printed circuit boards, if that is possible, and what methods you can use to take it off without damaging the board.

Can you remove the solder mask?

Let’s first talk about if this process is possible at all. Well, there is no exact or short answer to this question, and it ultimately depends on the circuit board you are using. It mostly depends on the type of coating you want to take away, and on the fact if you want to take all of it off, or if you want to just remove different areas on the product.

Experts suggest that if it is possible, you should steer away from trying to fully take off all of the coatings and that this could lead to damage to the board. Note that even though it is sometimes possible to do this task, it will most likely do some damage to the product, and you may end up with a faulty item.

If you want to take the solder mask the best thing you could do is first read all the manufacturer’s information, and see what it was made of. The way it was coated, and the materials used will make the biggest difference in the fact if this process is an option.

Note that in most cases, the short answer is, yes, you can safely remove the green coating, but the success of the operation depends on your skills, the method you choose as well as the PCB on its own.

On websites like pcbonline.com, you can learn why the color green was chosen for the boards, and you can find out more about the different types of coating.

Now, we are going to talk about some of the options you can and how you can utilize the best materials to do that. Note that the methods depend once again on your skills as well as the area you want to take off.

Always proceed with caution, and never try to do anything without having the proper tools, safety equipment, and don’t forget to do your research depending on the specific task at hand.

How to safely remove the coating?

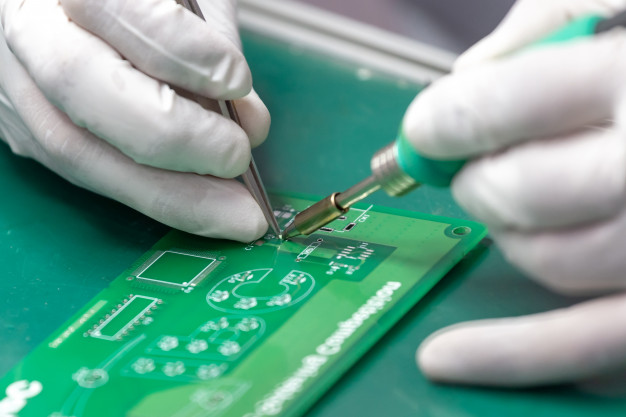

There are several methods you can use for this task, and the most popular one is grinding or scraping the excess of the solder mask.

For this method, you need to be really precise, and it is recommended that people who don’t have any specific skills steer away from trying to scrape the coating off. Note that for this technique, you can use any type of knife or a pick, and if you are a technician, you should not have any issues doing it.

The negative side of this method is that requires a lot of hand-eye coordination, and the whole process could take a lot of time. You need to do everything by hand, and you need to be extremely precise. The biggest pro for it is that you have full control over the operation, and if you have a steady hand and the right instruments, you will have no issues doing it.

The most effective technique is chemical peeling, and this method is used when you want to take off the coating from copper panels. Note that in case you choose to go with this option, you should always use a protective mask or tape in order to protect the other parts of the board from the chemicals you are going to use.

For this method, you will need to use a swab or a brush, and the negative side of it is that you won’t have full control of what you are doing. No matter how careful you are, you are still working with a liquid material that can easily spill or drop on paces where it is not supposed to go. The best thing about it is that this technique is extremely effective, the chemicals will easily dissolve the solder mask, and you will be done with it in just a fraction of the time needed for other methods.

The last technique we are going to cover here is micro blasting. Note that this is said to be the best option if you want to remove a specific part and if you want to do it with high precision. It is a great way to remove all the excess parts without damaging the board itself, and it is usually used by technicians who want to finish the PCB to perfection. The biggest negative of this method is that it can do serious damage to the product if the technician is not trained, so you have to have the needed skills to try this method out.

There are also other ways you can take of the excess solder mask of your printed circuit boards like milling and machining. Before trying any of these techniques out, you need to know what your purpose is, the area you want to take out, and your specific set of skills. Note that you should also pay attention to the material used to create the green coating, and you should also try to contact the manufacturer and ask them if they would recommend any specific action for this purpose. Be careful, always use the needed protective equipment, and if needed, you can always consult a professional and get this done by the experts.

Imagup General Magazine 2024

Imagup General Magazine 2024