In catering establishments or a meat processing company – fats and oils of vegetable or animal origin cannot be prevented from entering the wastewater outlet. Installation of filters and regular maintenance of drainage pipelines mitigate this problem.

Grease Changes Its Aggregate State

As is known, warm oils and fats are liquid and run off with wastewater. However, when the greasy matter cools – it thickens and begins to stiffen on the pipings. It goes into a solid-state and precipitates on the pipe walls.

Read more about wastewater treatment.

The deposits formed in this way become very solid. Often, they cannot be removed – even with the most modern pipe cleaning procedures. Therefore, it should not be allowed to enter the drainage system.

Dangerous Greasy Matters

The removal of greasy matters from the pipes is also important because it converts fat and oils into fatty acids through a chemical and biological reaction in water, which has a very unpleasant smell.

These acids are very aggressive and lead to corrosion. There are already known cases where fatty acids have damaged cast pipes although they are corrosion-resistant. There are even worse consequences in purification devices.

There, fats and oils are deposited in the rich sludge with microorganisms and prevent the necessary oxygen exchange. This makes biological wastewater treatment (clarification) almost impossible. Considering these aspects, it is logical that greasy matters should not enter the drainage system in excessive quantities.

How Does It Work In Households And Apartment Buildings?

If this happens, it should be removed from the water as quickly as possible. In drainage ordinances owned by cities and municipalities, the amount of greasy matters that may be discharged into the sewers is most often precisely determined. If one does not misuse household sinks to dispose of greasy matter from pots and pans, the limit is not exceeded when washing dishes. Therefore, the content of wastewater in residential buildings is usually not a problem.

From French Fries To Slaughterhouse

The situation is different for industrial plants that produce wastewater containing oils and fats. Drainage ordinances usually prescribe certain standards, so companies are required to do drainage through facilities with filters (separators) for the removal of grease.

This specifically means: Kitchen sinks in hotels, restaurants and canteens must be powered by filters. This requirement must be respected irrespective of the number of servings prepared daily. In addition to kitchens in restaurants or catering establishments, they also include small fast foods with French fries, etc. Filters/separators for the removal of the greasy matters must also be used in butchers, slaughterhouses, etc.

Special Filters

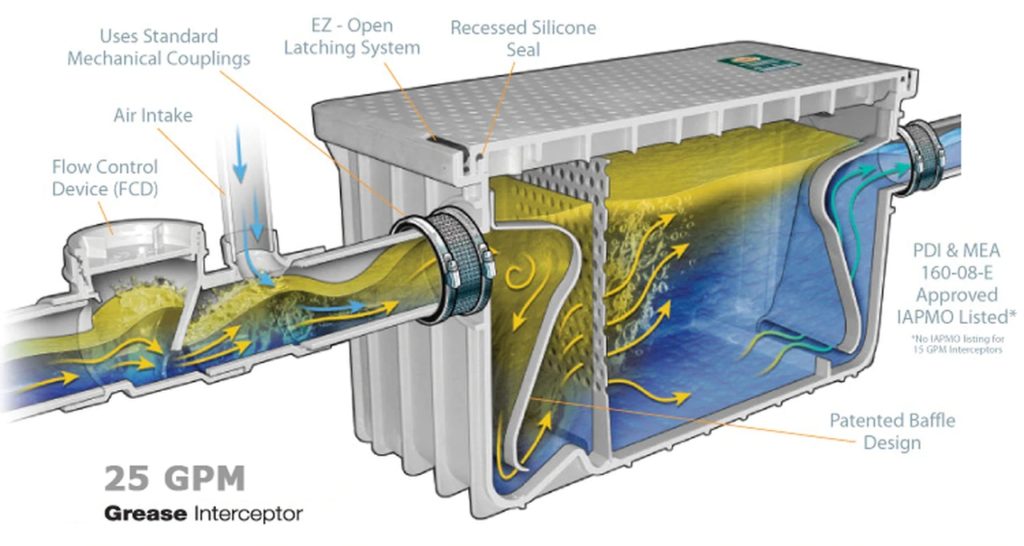

To separate the unwanted substance from the wastewater, we must bear it in mind that the grease floats on the surface. In this sense, we can also discuss the principle of gravity. Grease has a lower density than water. As soon as the water containing it subsides, greasy matters will be collected on the surface. Therefore, most filters comprise three chambers.

The Role Of Chambers In The Filter

The first chamber has the function of a sludge collector. It can be installed in the filter – or be a separate part. In both modes, it is important to keep the effluent flow rate low. Solids contained in wastewater, for example, sludge or debris, are falling to the bottom. In the second chamber, there is a real separation of greasy matter. At least once a month, and even better once in 14 days, it is necessary to remove everything collected there – regardless of how thick that oily layer is and whether the filter is “full” or not.

This is important because if the accumulated greasy matter stays in the filter for too long – it dissolves. Water-soluble fatty acids are formed in the water, which, with degreased water – reach the drainage system. The last chamber serves as a sampling pane and at the same time as a pane for submission, ventilation and inspection. Manually or automatically.

Grease Removal

In smaller companies, where not much greasy matter is released – this type of disposal is not very economically viable. But in big catering services like restaurants and hotels, some specific methods of removal are inevitable. For that purpose, you will call specialized companies such as phoenixgrease.com.

These companies provide you with professional services in every possible way – from grease trap installation, through grease trap cleaning to grease pumping. Special cleaning facilities or devices are used as a solution in these situations. This specialized machinery will take the greasy matter off, remove the captured sludge and help you maintain the filters in the right way. And all that without any mess or unpleasant smells.

What Do Grease Trap Cleaning Services Include?

These services usually include:

- Complete removal of greasy matter from the trap

- Washing and degreasing of walls and partitions of grease traps

- Testing the inlet and outlet of greasy matter in the trap assembly

- Disinfection of grease traps as needed

- Reporting necessary repairs or replacement of parts

- Regular or occasional inspection as agreed

Regular maintenance of these specialized traps prevents leaks and possible equipment malfunctions. We recommend a regular inspection arrangement as this can save you both – money and time in case of failure due to poor maintenance.

Grease Trap Cleaning – Equipment And Staff

Specialized vehicles for the ecologically safe collection of waste from the trap, as well as experienced workers, guarantee the quality of the grease trap cleaning services. A professional service is done by strict standards, and the waste is transported and treated following all applicable national laws and procedures.

Drainage Is A Separate System

Only those effluents containing content that has exceeded the permitted values can be run through the separator. Only after the removal of grease has been carried out should the “kitchen water” be mixed with normal wastewater.

So, kitchen drainage is a system unto itself. Neither wastewater nor sewage must be allowed to flow into the separator. Clearly, it is not a “purification pit.” The places from which the water containing the grease drains – must be fitted with stink preventers. However, this way, it cannot be prevented that a little grease always floats on the stopping water.

The Significance Of Grease Traps In Industry

Modern life courses require increasing care for the environment. We must consider pollution, materials used, wastewater discharged into the environment. For wastewaters – they are the easiest and least expensive to remove with the grease traps.

They are mainly made of lightweight materials, resistant to corrosion, porosity, etc. They are also waterproof, easy to maintain, lightweight and easy to install.

Conclusion

Grease traps are designed to separate the greasy matter most commonly found in wastewater from the kitchens of restaurants, hotels and other catering establishments. This also refers to the beef industry, the slaughterhouses, and the meat industries. The importance of traps that separate greasy matter from wastewater is that it also prevents the possibility of clogging the sewer system.

Imagup General Magazine 2024

Imagup General Magazine 2024